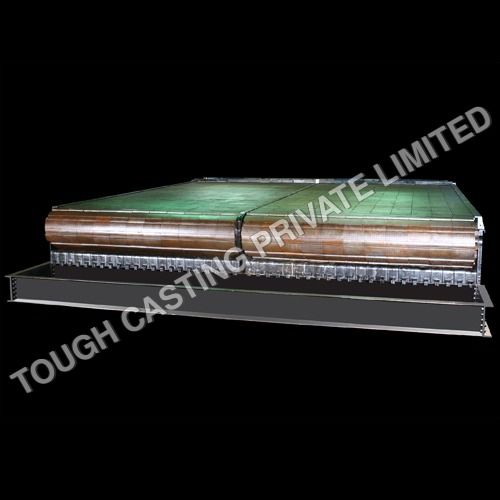

2 Hydraulic Drive Assly

Product Details:

- Product Type 2 Hydraulic Drive Assembly

- Material High-grade Alloy Steel

- Dimension (L*W*H) 550 mm x 340 mm x 220 mm

- Engine Type Hydraulic Motor Driven

- Speed 03600 rpm

- Power 7.5 kW

- Output Current NA (Hydraulic System)

- Click to View more

2 Hydraulic Drive Assly Price And Quantity

- 1 Unit

2 Hydraulic Drive Assly Product Specifications

- Variable, as per requirement

- Industrial Automation, Material Handling Equipment

- NA (Hydraulic System)

- 2 Hydraulic Drive Assembly

- 7.5 kW

- 03600 rpm

- 550 mm x 340 mm x 220 mm

- Hydraulic Motor Driven

- High-grade Alloy Steel

- Power Transmission and Torque Conversion

2 Hydraulic Drive Assly Trade Information

- 6ton Per Day

- 1week to 8 week Week

Product Description

Since inception, we are offering a world class range of 2 Hydraulic Drive Assly. These assemblies are designed under the guidance of veteran professionals by using optimum quality materials, iHaving ample resources in this domain, we provide pristine grade array of 2 Hydraulic Drive Assly to our valued patrons. With the use of quality-assured components and modern techniques, this product is manufactured by our adept professionals at our premises. Admired for its sturdy design, less maintenance and hassle free functioning, the offered 2 Hydraulic Drive Assly is demanded in varied industries like railway, automotive, marine etc.n compliance with international quality standards and norms. Our 2 Hydraulic Drive Assly is used in industries like railway, automotive, engineering and marine for circulating liquids to the closed loop circuits. Our clients avail these assemblies from us at competitive prices,

Features:

- Easy to operate

- Sturdy design

- Negligible maintenance

Versatile and Reliable Hydraulic Drive Assemblies

Our hydraulic drive assemblies are designed with versatility and reliability in mind, catering to power transmission and torque conversion needs in industrial automation and material handling. These units offer bidirectional rotation, multiple mounting types, and impressive efficiency of up to 92%. The corrosion-resistant finish and robust nitrile seals further ensure longevity and reduced maintenance. Their adaptability makes them suitable for a range of demanding industrial applications.

Engineered for Demanding Environments

Each assembly is constructed from high-grade alloy steel and equipped with high-performance nitrile rubber seals, supporting operations across harsh temperature ranges from -20C to +80C. Noise levels remain low even at full load, and the efficient design supports oil flow rates from 0 to 60 lpm. The hydraulic drives are precisely finished to withstand corrosion, ensuring hassle-free operation in challenging conditions.

FAQs of 2 Hydraulic Drive Assly:

Q: How should the 2 Hydraulic Drive Assembly be installed for optimal performance?

A: Installation should follow the specified mounting typeeither flange or foot mountedon a stable, flat surface. Ensure correct alignment of the splined or keyed input shaft and secure all connections. Proper hydraulic fluid and correct torque specifications as per the manufacturers guidelines are crucial for maximizing performance and longevity.Q: What benefits does the high-efficiency design (up to 92%) provide in industrial applications?

A: The high efficiency ensures reduced energy losses, lower operating costs, and improved performance consistency. This makes the hydraulic drive particularly beneficial for industrial automation and material handling, where continuous operation and reliable torque conversion are fundamental.Q: When should the seals be inspected or replaced in the hydraulic drive assembly?

A: Seals made from high-performance nitrile rubber should typically be inspected during routine maintenance intervals or if there are signs of leakage. Replacement frequency depends on operating conditions, but regular checks in demanding environments are recommended to maintain system integrity and prevent unplanned downtime.Q: Where can these hydraulic drive assemblies be used effectively?

A: These assemblies are ideal for integration into industrial automation systems and material handling equipment. Their robust construction and range of compatible speeds and pressures make them suitable for factories, warehouses, and other industrial settings requiring reliable power transmission.Q: What is the process for selecting the correct input shaft and housing finish?

A: Selection depends on the application: splined or keyed shafts are available based on torque and compatibility requirements, while housing finishes include corrosion-resistant paint or powder coat for enhanced durability. Consult the supplier or manufacturer to determine the optimal configuration for your environment.Q: How does the variable stroke and speed flexibility benefit end users?

A: Variable stroke and speed (03600 rpm) allow for precise control over movement and power delivered, accommodating diverse operational needs. This adaptability is particularly advantageous in applications where load and speed requirements vary frequently, optimizing productivity and equipment performance.Q: What maintenance practices can extend the life of these hydraulic drive assemblies?

A: Regularly change hydraulic fluid, inspect seals and external finishes for wear or corrosion, and ensure the drive is operated within specified temperature and pressure parameters. Keeping the assembly clean and monitoring for unusual noise or vibrations will also help prolong service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Combustion System' category

|

TOUGH CASTING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |