Boiler Combustion Systems

Product Details:

- Product Type Boiler Combustion Systems

- Material Mild Steel

- Dimension (L*W*H) Customizable

- Engine Type Industrial Burner System

- Speed Variable, as per system design

- Power As Required

- Function Efficient Fuel Combustion for Steam Generation

- Click to View more

Boiler Combustion Systems Price And Quantity

- 1 Unit

Boiler Combustion Systems Product Specifications

- Boiler Combustion Systems

- As Required

- Efficient Fuel Combustion for Steam Generation

- Customizable

- Industrial Burner System

- Mild Steel

- Variable, as per system design

- Industrial Boilers, Heating Systems

Boiler Combustion Systems Trade Information

- 6ton Per Day

- 1week to 8 week Week

Product Description

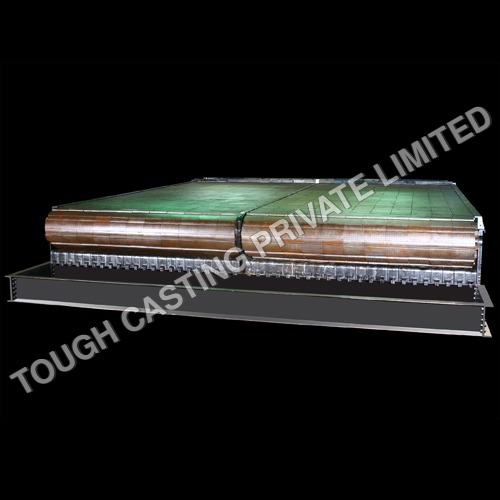

Boiler Combustion systems (with photo of Travelling Grate)

We are an ISO certified manufacturer, engaged in manufacturing and exporting an exclusive range of Boiler Combustion Systems. These combustion systems are designed for feeding different types of biomass including wood chips, waste wood, sawdust, agro waste and rice husk into the boiler. In order to manufacture these Boiler Combustion Systems, our engineers use quality tested materials procured from the authentic vendors. We can also offer these systems to the clients at nominal prices.

Features:

- Silent operation

- Zero maintenance

- Enhanced service life

Further Details:

We supply various combustion systems like Travelling Grate, Dumping Grate, Reciprocating Grate etc, as per requirement of projects. The Travelling Grate can be used on any kind of fuel firing with casting parts made with special grades which can withstand higher temp.

Description

We are specialised in design, mfg & supply of various combustion systems like Travelling Grate, Dumping Grate, Reciprocating Grate etc, as per requirement of projects. The Travelling Grate can be used on any kind of fuel firing with casting parts made with special grades which can withstand higher temp.

Advanced Automation for Reliable Performance

Equipped with easy-to-integrate PLC or relay-based control systems, these boilers deliver consistent automation for critical industrial operations. Users benefit from simple interface options that ensure smooth fuel management and adaptive speed as per system needs, enhancing safety and peace of mind during steam generation processes.

Flexible Fuel Compatibility and Customization

Our combustion systems seamlessly handle oil, gas, or dual-fuel mixtures, allowing operational flexibility according to resource availability. With customizable burner capacity, dimension, color, and mounting style, they are tailored to meet the diverse requirements of industries and site-specific constraints, ensuring a perfect fit each time.

High Efficiency and Easy Maintenance

Designed to reach up to 95% combustion efficiency, our burners translate to substantial fuel savings and reduced emissions. Constructed from mild steel for robustness, and available with manual or electronic ignition, they facilitate both reliable performance and simplified maintenance for uninterrupted industrial workflow.

FAQs of Boiler Combustion Systems:

Q: How does the automation in these Boiler Combustion Systems benefit industrial operations?

A: Automation via PLC or relay-based control enables consistent fuel management, precise temperature control, and real-time monitoring. This results in greater reliability, reduced manual intervention, and enhanced operational safety for critical industrial heating and steam generation applications.Q: What types of fuels can be used in these combustion systems?

A: Our combustion systems support oil, gas, or dual-fuel configurations, allowing users to operate using the most suitable or available fuel source. This flexibility optimizes cost-effectiveness and ensures continuous operation in diverse industrial settings.Q: When should I consider a customized burner capacity for my boiler system?

A: Customization is advisable when standard burner capacities do not meet your facilitys steam demand, space restrictions, or integration needs. By tailoring burner size and features, you ensure maximum efficiency and compatibility with your existing setup.Q: Where are these combustion systems typically installed?

A: These systems are primarily installed in industrial boilers, heating plants, or steam generation facilities. With options for flange or on-skirt mounting and customizable dimensions, they can be integrated into new projects or retrofitted into existing infrastructure.Q: What is the process for ignition in these boiler burners?

A: Ignition can be initiated either electronically or manually, depending on the chosen model. This dual-method approach offers operational flexibility and ensures safe, reliable start-up in all working environments.Q: How do users benefit from the high combustion efficiency of these systems?

A: With combustion efficiency of up to 95%, users experience significant fuel savings, reduced emission output, and improved overall energy utilization, resulting in lower operating costs and environmental impact.Q: What are the maintenance requirements for these combustion systems?

A: Thanks to their simple design, durable mild steel construction, and flexible ignition systems, routine maintenance is straightforward. Regular inspection and cleaning ensure sustained performance, while PLC/relay diagnostics facilitate early detection of potential issues.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Combustion System' category

|

TOUGH CASTING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |