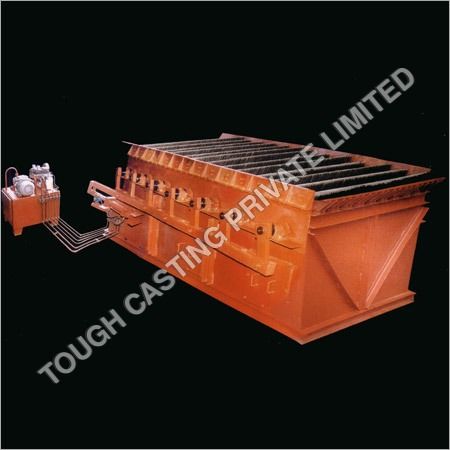

Reciprocating Grate

Product Details:

- Product Type Reciprocating Grate

- Material Cast Iron / Stainless Steel

- Dimension (L*W*H) Customizable as per requirement

- Speed Adjustable via Motor Drive

- Power Electric Motor Driven

- Output Current Depends on Motor Specification

- Stroke Reciprocating Motion

- Click to View more

X

Reciprocating Grate Price And Quantity

- 1 Unit

Reciprocating Grate Product Specifications

- Industrial Boilers, Waste Incineration, Biomass Plants

- Reciprocating Motion

- Cast Iron / Stainless Steel

- Electric Motor Driven

- Depends on Motor Specification

- Adjustable via Motor Drive

- Customizable as per requirement

- Fuel Feeding and Burning

- Reciprocating Grate

Reciprocating Grate Trade Information

- 6ton Per Day

- 1week to 8 week Week

Product Description

We are an ISO 9001:2008 certified manufacturer and exporter, engaged in offering an utmost range of Reciprocating Grate. These systems are used for the combustion of a wide range of feed materials including wood chips, bark, sawdust, forest waste, agricultural waste and rice husk. Our Reciprocating Grate is designed at our state of the art manufacturing plant by using top quality materials, in sync with the norms set by international market. We offer these products to the clients at reasonable prices.

Features:

- Maintenance free

- Enhanced service life

- User friendly design

| Condition - | New |

| Dimension(L*W*H) - | 6500 X 2300 X 3000 |

| Hot Air Temperature - | 800-900 Degree C |

| Output - | Hot Air |

| Pressure - | Low Pressure |

| Structure - | Direct Heating |

| Style - | Horizontal |

| Type - | Once Through |

| Usage - | Industrial |

| Weight - | 30 Tons |

| Heat Output - | 600,000-12,000,000 Kcal/H |

| Fuel - | Wood Chips / Boimass Solid Fuel |

Heavy-Duty Construction for Long-Term Use

Designed with cast iron or stainless steel, this reciprocating grate ensures integral strength and superior durability. Its heavy-duty build is tailored for continuous operation, meeting the demands of industrial-scale combustion processes. The heat-resistant coating further protects critical components, ensuring reliable performance at temperatures up to 1200C.

Customizable Performance and Flexible Operation

Capacity, dimensions, and bar thickness are fully customizable, allowing the system to adapt to specific project requirements. The option of automatic or semi-automatic modes, along with PLC integration, offers operational flexibility and precise process control, ensuring efficient fuel handling and burning for various industrial applications.

Versatile Fuel Compatibility and Efficient Burning

Engineered for compatibility with biomass, municipal solid waste, coal, and wood chips, this grate delivers robust fuel feeding and combustion performance. Its reciprocating motion and adjustable speed ensure optimal thermal efficiency, supporting sustainable waste-to-energy processes and reliable energy production.

FAQs of Reciprocating Grate:

Q: How does the reciprocating grate system operate in industrial applications?

A: The reciprocating grate uses an electric motor-driven mechanism to feed and burn fuel via a reciprocating motion. This motion ensures continuous movement of fuel across the grate bars, promoting efficient combustion and consistent throughput in processes like biomass plants, industrial boilers, and waste incinerators.Q: What is the process for customizing the grates capacity and dimensions?

A: Customization is achieved during design and manufacturing, where parameters like capacity (up to 100 TPH), grate bar thickness (16 mm to 32 mm), and physical dimensions (L*W*H) can be specified based on customer requirements and application needs, ensuring an optimal fit for diverse industrial settings.Q: When should I use the PLC (Programmable Logic Controller) option for control?

A: The PLC option is ideal for facilities requiring advanced automation, precise process control, or integration with other automated systems. PLCs enable real-time monitoring, adjustable speed control, and tailored operational sequences, increasing efficiency and reducing manual intervention.Q: Where is the reciprocating grate commonly installed?

A: These grates are typically found in industrial settings such as biomass-fired power plants, waste-to-energy incinerators, coal-fired boilers, and facilities processing municipal solid waste, both in India and globally. Their robust design makes them suitable for continuous, high-capacity operations.Q: What maintenance is required for this reciprocating grate system?

A: Routine inspection and minor cleaning are usually sufficient thanks to its low-maintenance design. The use of high-grade materials and a heat-resistant coating minimizes wear and prolongs component lifespan, reducing the frequency and cost of downtime repairs.Q: How does the reciprocating motion benefit fuel burning efficiency?

A: The reciprocating motion continuously moves fuel over the grate, enhancing air distribution and facilitating thorough combustion. This results in higher efficiency, reduced unburned residue, and improved energy output from a variety of fuels, including biomass and waste.Q: What are the main benefits of using this reciprocating grate for my industrial facility?

A: Key benefits include robust, continuous operation, high-temperature resistance, low-maintenance requirements, and customizable options for compatibility with different fuels and capacities. These features support efficient energy recovery and make the system cost-effective and reliable for long-term use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

TOUGH CASTING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |